Belusso panels are intended for indoor installation. The product is intended for finishing wall surfaces in both dry and wet areas. Correct installation and maintenance will ensure long-term use of Belusso panels. The manufacturer is not liable for damages related to improper installation or poor mounting conditions.

For instructional videos and manuals, you can view this here Finding.

Here you can find our color guide for grouting.

Accessories

Also, don't forget to order your accessories along to make installation flawless

Wall Panels Installation

Acclimatization

Before installation, the wall panels must be acclimated to the room temperature at the installation site. The room where the tiles are installed should be between 15°C - 30°C [59°F - 86°F]. They should be stored horizontally on an even surface under controlled environmental conditions.

- Circular saw with guide rail

- Cutting wheel - discs with sufficient teeth are recommended, for example, ø165mm (56 teeth) and ø350mm (108 teeth)

- Universal knife

- Ruler, tape measure, pencil

- Distance crosses, clamps for leveling tiles

- Glue trowel, sealant squeezer

- Broom or vacuum cleaner

- Optional: table saw, hole saw, jigsaw, mounting clamp

Surface preparation

Wood (OSB, MULTIPLEX)

- Wood substrates must be firmly attached to the base structure; The Wall Tiles must not be mounted on unstable, poorly attached baseboards.

- The substrate must be load-bearing, dry, clean and degreased.

- The surface must be stable and free of cracks, bends and unevenness.

Concrete, Brick

- All loose and unstable elements must be removed from the surface.

- Any bulges in the substrate should be removed by sanding; the voids can be filled with suitable filler and then primed.

- The substrate must be hardened and tempered according to the recommendations.

Ceramic Tiles, Terrazzo, Stone

The existing substrate must be firmly attached to the subfloor; do not attach the wall panels to unstable, poorly attached tiles.

- The surface of the tiles must be thoroughly cleaned and degreased before applying the adhesive.

Equalization

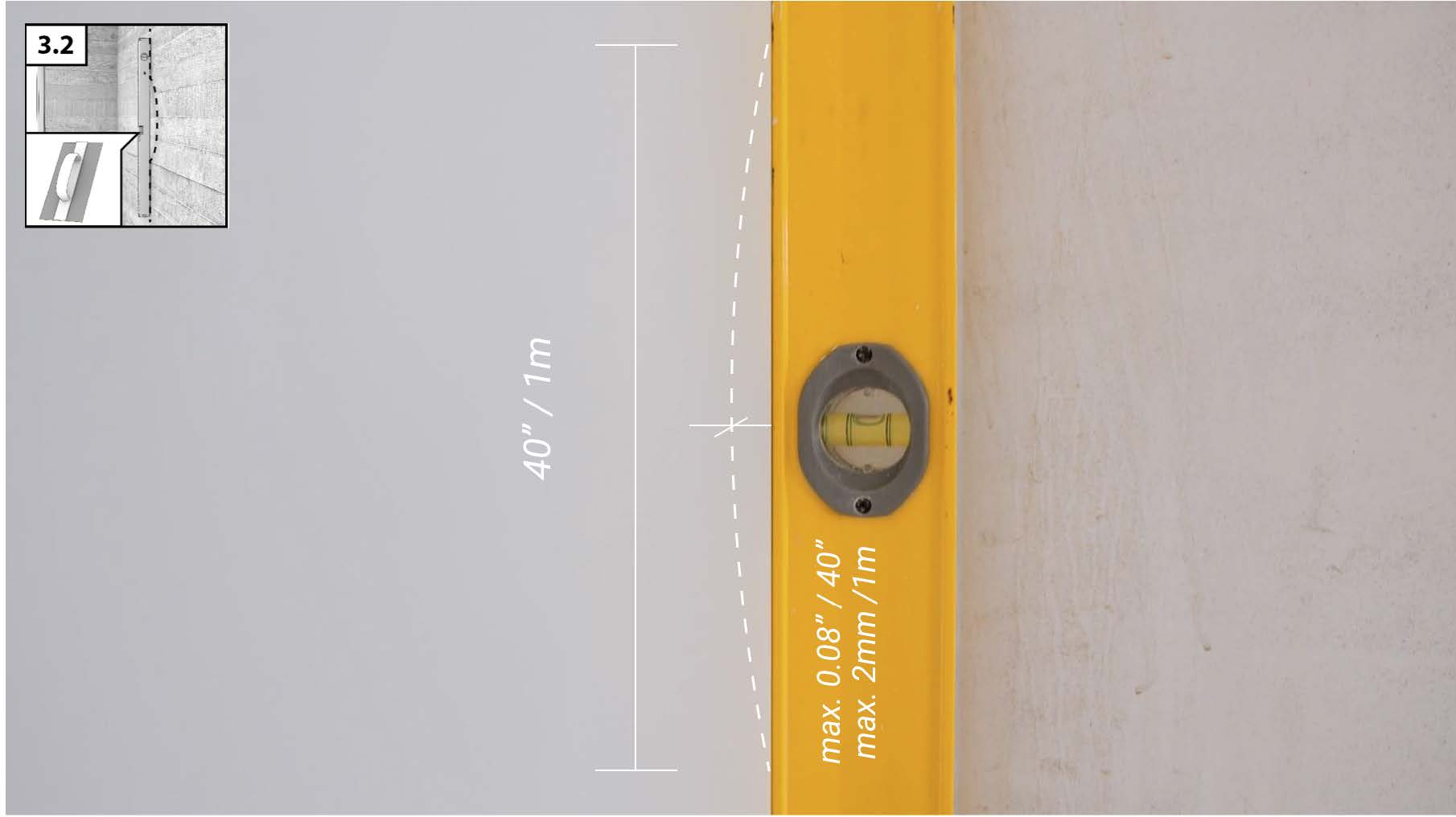

The substrate shall be leveled within a maximum of 2 mm per 1 meter in length [0.08 inch per 40 inches]. No unevenness, deflection and defects

Cleaning surface

Clean the wall of dirt and dust and degrease it if you are installing it on a non-absorbent surface. The surface should be even and stable.

Area Measurement

Before starting the installation, measure the lengths of the walls on which the wall panels will be installed. A well-planned layout of the panels will avoid very narrow elements and allow you to maintain proportions.

Cutting wall panels

Cut the panels using a circular saw with a guide. For cutting, we recommend using discs with a sufficient number of teeth, for example, ø165 mm (56 teeth) and ø350 mm (108 teeth). Be sure to cut the panel with the decorative surface facing up. If there are electrical outlets or other installation components on the wall surface, cut holes in the panel before installing it. Depending on the shape, the holes can be cut with a hole saw or a jigsaw.

Clean the panel

The cut panels must be cleaned. The lower surface of the panels to which the adhesive will be applied must be free of dust, dry and degreased to ensure proper adhesion of the adhesive.

Application of glue

Attaching mounting tape

Glue the double-sided mounting tape vertically to the surface of the substrate. This ensures even distribution of the adhesive and facilitates installation and holds the panels in place until the adhesive cures. The tape should be applied at even, approximately 20-45 cm intervals (depending on the wall surface).

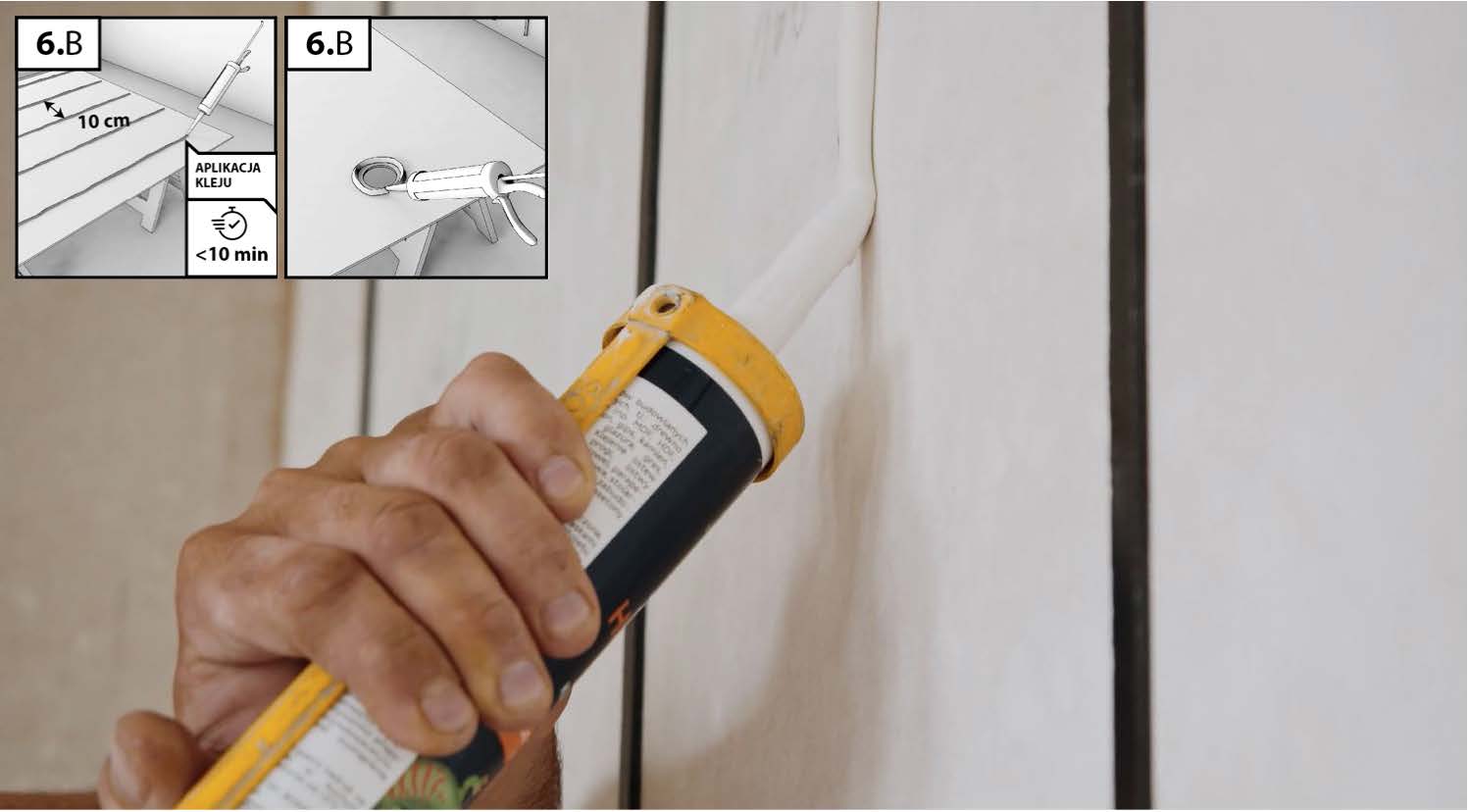

Apply glue

Apply mounting adhesive to the underside of the panel or wall surface. If you are using glue from a cartridge or foil pack, apply it in vertical stripes at 10-cm intervals. Do not apply the glue in dots. Apply glue under the perimeter of each cut opening. The glued surfaces should be joined within 10 minutes of applying the glue.

Apply glue with a putty knife

Apply the mounting adhesive to the underside of the panel or wall surface. Apply the adhesive to the entire surface of the panel to be glued. Do not apply the adhesive in dots. The adhesive is applied with a putty knife (C1) in a layer of 4x4x4 mm. The glued surfaces must be joined within 40 minutes of applying the adhesive.

Application of panels to the surface

After the glue is applied, place the panel against the wall and press it down. For optimum strength, press the elements to be glued so that there is a 2-3 mm ventilation gap between them. This gap allows the glue joint to permanently transfer the deformation.

Leveling the panels

After gluing the first panel, place the leveling clips - these will provide the expansion joint between the panels (2-3 mm) and facilitate surface leveling. After applying the next panel, level the adjacent surfaces. Do not remove the leveling clips until the adhesive has cured. Continue mounting the next panels.

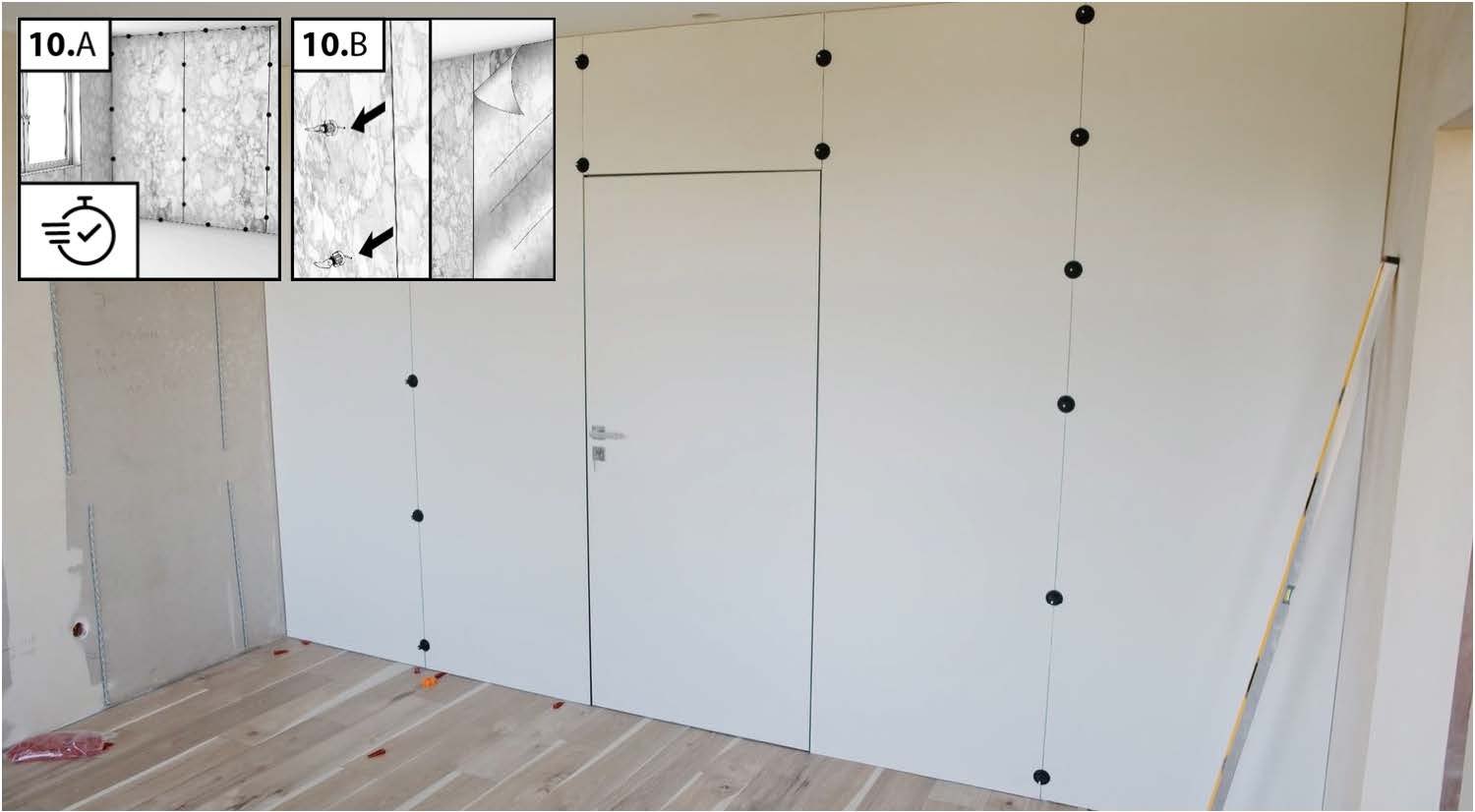

Removal of the clips and protective film

The curing speed of the adhesive depends on the ambient temperature and humidity (24-48 hours). As the temperature and humidity increase, the polymerization process is faster. Ensure effective ventilation until complete curing is achieved. After completing the work and setting the adhesive, remove the leveling clips and then the protective film from the surface of the panels.

Joint filling

Expansion joints should be filled with a flexible grout (epoxy, silicone) or with special finishing profiles. Before applying the grout, protect the surfaces along the expansion joint with painter's tape - this facilitates the grouting process and protects the surfaces from dirt. The profiles should be installed during the assembly of the panels. To install the profiles, use the same glue that you use to glue the panels. During installation, fill the internal surfaces of the profiles with silicone to seal the joint between the profile and the panel.

Cleaning the panels after installation

The surface of the panels can be used immediately after installation. Remove dust and dirt with Rocko Tiles cleaning solution. Wipe the panels with a damp, not too fluffy cloth (preferably microfiber). Do not use wire or nylon sponges that may damage the surface.